'What is - and how to vac form? The info is not specific to Classic Cylon Centurions, but SURE can be helpful for them and many, many others projects. Here you'll find various threads with great info from our members for the hobby of costuming.

-

Big Al

- Command Centurion

- Posts: 1012

- Joined: Tue Jun 07, 2011 3:09 am

- Location: Las Vegas Nevada

Post

by Big Al » Tue Jul 05, 2011 7:48 pm

Tools and Cutting Machines

Making Plugs or Molds from Foam or wood is the most labor intensive phase of any build. The more detail and quality you put into your plug the more professional your part will look when it's finished.

Tools and Cutting Machines

Making Plugs or Molds from Foam or wood is the most labor intensive phase of any build. The more detail and quality you put into your plug the more professional your part will look when it's finished.

You WILL spend hours cutting and shaping your Plug or Mold and not haveing the right tools can make this phase even longer or worse trying to utilize a tool that was ment for another task, then making a wrong move with the wrong tool ruining your Plug or mold and having to start over.

There is nothing more frustrating than when you are working on somthing and you do not have the right tool.

Besides having regular guy tools like Hand tools and common power tools, In order to carve and shape Foam or Wood, you will need some special tools that will make your job a lot easier.

Lets start with hand tools and move to power tools

No model shop is complete without a good set of hand tools.

I'm not going to talk about common tools that everybody has, or bore you to death with the over stated standard safety lecture/disclosure about power tools and what measures you should take to be safe.

Every time I read a book about a subject that involves tools, it seem that at least the first 30% of the book is dedicated to safety and drones on page after page after page about Safety.

ALL TOOLS can be dangerous and everybody knows the drill (No pun intended) so just be safe! Nuff said.

So let's get to the meat!

Knives

Knives

No matter what your material is, (Foam or Wood) it's a good idea to purchase a good set of scalpel knives.

A good set of Scalpel knives are must for any well equipped model shop.

This set is made by Excel and is a good one! This set is available through Tower Hobbies.

[attachment=4]Excel Knife Set.jpg[/attachment]

I like this one because it has a variety of Scalpel knifes, Gouging blades, Draw hoop knives, Sanding block and also includes a miter box and a razor saw.

Tower Hobbies Excel Set

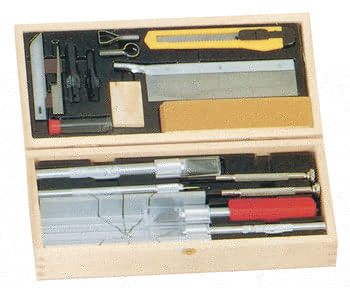

This next set is made by X-Acto and is a very nice set and you will use every tool in this box!.

The set includes, a draw knife, a variety of Knife blades and knife handles, small sanding block, Edge cutter, Razor plane and a coping saw!

[attachment=3]xacto set.jpg[/attachment]

You can get this set through Tower Hobbies

Razor Saws

Razor Saws

Razor saws are just as important as knives and other shaping tools. They come with course or fine teeth , wide and skinny and some are even made with a thin steel to make a minimum Cerf. (The amount of material that is removed by the saw blade)

Zona, Excel and X-Acto make Razor saws. X-Acto and Excel make a chuck handle with separate blades. Zona has a similar version of this except theirs is a clamp handel. Zona makes a 3 in 1 and a 4 in 1, and as handy as they are, (I have all 3) they are like a universal screw driver with changeable bits. Every time you need a different tool, you have to stop and change the blade.

Zona makes a variety of stand alone saws and I recommend these because when your in the groove, You can just set one tool down and grab another and continue your work.

Here are some examples.

Here are some examples.

[attachment=2]Zona 14.jpg[/attachment]

[attachment=1]Zona 52.jpg[/attachment]

[attachment=0]Zona Saber.jpg[/attachment]

These can also be purchased from Tower Hobbies and here is the link

Tower Hobbies Zona Saws

All of these tools will help you make your plugs! you will also need a good colection of sanding implements and that's next!

Next Up: Sanding Blocks and Power Sanders

-

Attachments

-

- Zona Saber.jpg (13.81 KiB) Viewed 15088 times

- Zona Saber.jpg (13.81 KiB) Viewed 15088 times

-

- Zona 52.jpg (11.85 KiB) Viewed 15088 times

- Zona 52.jpg (11.85 KiB) Viewed 15088 times

-

- Zona 14.jpg (14.59 KiB) Viewed 15088 times

- Zona 14.jpg (14.59 KiB) Viewed 15088 times

-

- xacto set.jpg (23.05 KiB) Viewed 15088 times

- xacto set.jpg (23.05 KiB) Viewed 15088 times

-

- Excel Knife Set.jpg (23.38 KiB) Viewed 15088 times

- Excel Knife Set.jpg (23.38 KiB) Viewed 15088 times

Last edited by

Big Al on Fri Aug 12, 2011 11:50 pm, edited 2 times in total.

By Your Command

-

GoldCylon

- Founder

- Posts: 6948

- Joined: Fri Dec 02, 2005 3:02 pm

- Location: Sacramento

-

Contact:

-

Post

by GoldCylon » Tue Jul 05, 2011 8:15 pm

Those Xacto sets puts my box to shame. Time to upgrade.

-

Big Al

- Command Centurion

- Posts: 1012

- Joined: Tue Jun 07, 2011 3:09 am

- Location: Las Vegas Nevada

Post

by Big Al » Tue Jul 05, 2011 8:33 pm

GoldCylon wrote:Those Xacto sets puts my box to shame. Time to upgrade.

It really pays to invest in these sets when your making plugs. Everyone has the basic pencil knife type but you really need more than that when your cutting and shaping.

The devil is in the details and it's no different here.

The more detailed you want to make somthing, the more specialty tools you will need for making quality, intricate shapes.

Just my opinion.....

Big Al

By Your Command

-

Big Al

- Command Centurion

- Posts: 1012

- Joined: Tue Jun 07, 2011 3:09 am

- Location: Las Vegas Nevada

Post

by Big Al » Wed Jul 06, 2011 1:31 pm

SandPaper

Sandpaper is a subject that can be discussed in great detail but isn't really necessary.

SandPaper

Sandpaper is a subject that can be discussed in great detail but isn't really necessary.

There is no perfect selection of grit when sanding. You just have to use common sense.

Grits vary, so start with a course to semi-course grit for rough shaping, then graduate to a medium grit for final shaping, and then a fine to super fine for a finished or polished surface.

If you are making your plug from a hard wood, the course grits are needed because you want to remove a lot of material in the beginning to form the shape of your plug.

The Grit numbers are representative of grains of sand per square inch on the paper.

30 and 60 grit sand paper is basically boulders glued to paper and will tear up your material with one pass.

(Not recommended for this type of work.)

[attachment=3]60_Grit_Sandpaper_by_Dragonhead.jpg[/attachment]

A good starting point for Balsa or Foam would be 100, 120 to 160 for a starting grit.

[attachment=1]100 grit sand paper.jpg[/attachment]

A medium would be 200 to 600 grit

[attachment=2]200 grit sandpaper.jpg[/attachment]

Fine to super fine would be 1000 to 2000 grit for finish and polishing, 2000 grit is mostly used to polished headlight lenses on cars. and believe it or not, a paper grocery bag makes a great Super Duper fine sandpaper for polishing. (Is Super Duper a word?)

[attachment=0]2000 sandpapers.jpg[/attachment]

Just remeber that a polished finished on your plug is not desirable and if your finished plug is polished, it will trap air and cause bubbles in your part.

You can read all of this info on sandpaper and still not know which paper to use. the best way is to just try it!

Next up: Sanders (Manual Hand Held)

-

Attachments

-

- 2000 sandpapers.jpg (17.07 KiB) Viewed 15085 times

- 2000 sandpapers.jpg (17.07 KiB) Viewed 15085 times

-

- 100 grit sand paper.jpg (158.35 KiB) Viewed 15085 times

- 100 grit sand paper.jpg (158.35 KiB) Viewed 15085 times

-

- 200 grit sandpaper.jpg (15.3 KiB) Viewed 15085 times

- 200 grit sandpaper.jpg (15.3 KiB) Viewed 15085 times

-

Last edited by

Big Al on Fri Aug 12, 2011 11:51 pm, edited 2 times in total.

By Your Command

-

Big Al

- Command Centurion

- Posts: 1012

- Joined: Tue Jun 07, 2011 3:09 am

- Location: Las Vegas Nevada

-

Big Al

- Command Centurion

- Posts: 1012

- Joined: Tue Jun 07, 2011 3:09 am

- Location: Las Vegas Nevada

-

Big Al

- Command Centurion

- Posts: 1012

- Joined: Tue Jun 07, 2011 3:09 am

- Location: Las Vegas Nevada

Post

by Big Al » Thu Jul 07, 2011 1:40 am

Power Sanders

Power sanders are a must but not all power sanders are appropriate for this kind of work

Power Sanders

Power sanders are a must but not all power sanders are appropriate for this kind of work

I will show you what sanders I have and you don't need every one of these sanders but it helps.

I stuck with pics of the Ryobi products because I'm not a pro carpenter and the ryobi products are the least expensive and are sutable for model work not to mention they work great!.

If you have deep pockets you can get these same tools in another brand such as DeWalt, Makita, Bosh. But as much as these brands are premium tools, It's really not necessary.

Basic Palm Sander

Basic Palm Sander

Ok everybody has seen these so not alot to explain.

You put the paper on it, turn it on and and start sanding!

High Vibration does the work.

[attachment=5]Ryobi palm_sander.jpg[/attachment]

Draw back, the vibration is circular and can leave undesirable discernible swirling grooves in your work.

This sander is best used for initial rough shaping.

Orbital Palm sander

Orbital Palm sander

This one is pretty cool in that the pad is round and rotates while it vibrates.Variable speed

the therory is, Rotation with vibration prevents pattern grooving.

[attachment=4]Ryobi Orbital Sander.jpg[/attachment]

Draw back, Nothing is perfect. Hard to get close to edges and corners.

This sander is best for medium finish work.

Corner Sander

Corner Sander

Great tool! vibration sander with a clothes iron shaped pad allows you to get into corners and some tight places you can't get to with an orbital sander.

[attachment=3]Ryobi Finishing palm sander.jpg[/attachment]

Draw back, can cause the same grooves as the basic palm sander.

This is a Great finish sander!

Finish Sander

Finish Sander

Much smaller triangle pad head with a 90 degree angle and a slender motor body.

Makes it very easy to finish sand and can reach places the other palms can't.

[attachment=2]Ryobi Finsh sander.jpg[/attachment]

Draw Back Versatility is limited to the triangle head (No other attachments)

Awsome finish sander!

Dremel Shaping sander

Dremel Shaping sander

I got this one some years ago and I don't know if they still make it or replaced it with a new model but if you can find one grab it!

I use this for just about every shape you can think of and it works great!

[attachment=1]Dremel shape sander.jpg[/attachment]

This is a close up of the different shaped rubber sanding forms.

it also has an attachment pad for finish work!

[attachment=0]Dremel shape Sandingforms.jpg[/attachment]

Draw backs, Can't think of any.

Ok that does it for the palm sanders and hand sanders.

Next Up: Bench Sanders

-

Attachments

-

-

-

-

- Ryobi Finishing palm sander.jpg (15.34 KiB) Viewed 15079 times

- Ryobi Finishing palm sander.jpg (15.34 KiB) Viewed 15079 times

-

- Ryobi Orbital Sander.jpg (10.65 KiB) Viewed 15079 times

- Ryobi Orbital Sander.jpg (10.65 KiB) Viewed 15079 times

-

- Ryobi palm_sander.jpg (8.28 KiB) Viewed 15079 times

- Ryobi palm_sander.jpg (8.28 KiB) Viewed 15079 times

Last edited by

Big Al on Fri Aug 12, 2011 11:54 pm, edited 2 times in total.

By Your Command

-

Big Al

- Command Centurion

- Posts: 1012

- Joined: Tue Jun 07, 2011 3:09 am

- Location: Las Vegas Nevada

Post

by Big Al » Thu Jul 07, 2011 4:37 am

Bench Sanders

Bench sanders are great for rough shaping any type of material when you are bringing a blank to a desired shape.

Bench Sanders

Bench sanders are great for rough shaping any type of material when you are bringing a blank to a desired shape.

they are also handy for cleaning edges, straightening or smoothing flat surfaces or any kind of general sanding work.

There are only 4 so this section will be short.

1 Inch Bench Top Belt Sander

1 Inch Bench Top Belt Sander

Great tool, used mostly on smaller parts.

[attachment=0]belt-sander.jpg[/attachment]

4x36 Belt/6 Inch Disc combo sander

4x36 Belt/6 Inch Disc combo sander

Many uses for this one and is a must for any model shop.

The belt can be set to vertical or horizontal.

[attachment=5]Ryobi Bench sander.jpg[/attachment]

Ocilating Spindle Sander

Ocilating Spindle Sander

This is one of my favorites and is very versatile.

Good for straight edges but mostly for curved shapes.

Comes with a selection of spindles sizes for different radius curves.

One of the best tools I have ever owned! and I would recommend this to anyone modeling and fashioning parts of any kind!

[attachment=4]Ryobi Spindal sander.jpg[/attachment]

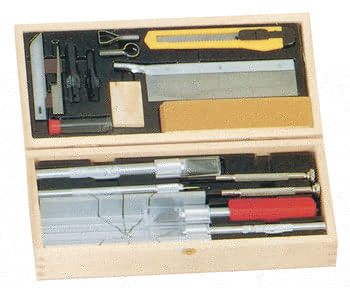

Bench Top Drill Press

Bench Top Drill Press

Yes there is nothing special about this tool and it's main objective is to bore holes in things.

[attachment=3]Ryobi Drill Press.jpg[/attachment]

The reason I included it here is because you can buy spindels for it and Viola! it's another sander.

[attachment=2]Drill press sanding spindles.jpg[/attachment]

I have also used it as a vertical lathe for spinning things like nose cones or cylinder type parts.

As your part spins, you can sand it easily by stroking a piece of sandpaper up and down against your part by hand.

This is not my work but I have done this many times.

This is a Blue foam nose cone Plug for a WWII spitfire Model.

[attachment=1]spitfire02.jpg[/attachment]

Ok that about covers all the sanders. As you can see, the sander arsenal is vast and though the subject is a little dry, I wanted to cover it because like I said earlier, Sanding is 80% of the labor.

There is no one sander that will do everything that's why there are so many of them.

Power sanders do not replace Hand sanders and getting great detail requires great sanding whether you are working with wood or foam, a good selection of sanders and paper will make your parts astonishingly professional.

Sanding skills come with practice and time and owning all of the tools won't give you instant skills. Although owning all the tools will help you hone your skills if you put the time in to learn how to manipulate and utilize your sanders to achive the parts you desire.

No candy coating here ,Sanding is very laborious and alot of guys run away from the very thought of spending hours on end sanding a part.

My advice to you is to embrace the sanding as this is the secret to perfect creations.

The more you sand the better you get! and the better your project looks in the end.

There are no short cuts in sanding, and just like playing an musical instrument, the key is Practice, Practice, Practice.

There are 3 phases to sanding

There are 3 phases to sanding

Rough shaping

Rough shaping

Contour Shaping

Contour Shaping

Smoothing or finishing

Smoothing or finishing

Each one requires a different technique and a different touch.

Next Up: Power Cutting Tools

-

Attachments

-

- belt-sander.jpg (8.17 KiB) Viewed 15045 times

- belt-sander.jpg (8.17 KiB) Viewed 15045 times

-

-

- Drill press sanding spindles.jpg (19.73 KiB) Viewed 15077 times

- Drill press sanding spindles.jpg (19.73 KiB) Viewed 15077 times

-

-

- Ryobi Spindal sander.jpg (10.16 KiB) Viewed 15077 times

- Ryobi Spindal sander.jpg (10.16 KiB) Viewed 15077 times

-

- Ryobi Bench sander.jpg (26.51 KiB) Viewed 15077 times

- Ryobi Bench sander.jpg (26.51 KiB) Viewed 15077 times

Last edited by

Big Al on Fri Aug 12, 2011 11:57 pm, edited 3 times in total.

By Your Command

-

Big Al

- Command Centurion

- Posts: 1012

- Joined: Tue Jun 07, 2011 3:09 am

- Location: Las Vegas Nevada

Post

by Big Al » Thu Jul 07, 2011 6:34 am

Power Cutting Tools

This is where we talk about powered cutting and carving tools.

Power Cutting Tools

This is where we talk about powered cutting and carving tools.

Table saws and circular saws are always good to have and there is no reason to go into details about those as you do not have to have them to make great parts.

Scroll Saw

Scroll Saw

The first saw that is a must is a scroll saw. Excellent saw for highly detailed very intricate cutting.Mostly for wood but will also cut foam although not the preferred method.

This is what I use for pattern cutting

[attachment=6]Ryobi Scroll Saw.jpg[/attachment]

Draw back, Material thickness is limited.

You can spend thousands on precision scroll saws and if you want to do intense, intricate, precision, scroll work, like making Cuckoo clocks, you will need one.

For our purpose, that kind of precision is not necessary.

I have owned at least 5 inexpensive scroll saws over the years, some were good and some were boat anchors.

out of all of the scroll saws I have owned , this one is the best.

Bench Top Band Saw

Bench Top Band Saw

I use this one alot, Sometimes for pattern cutting but mostly for removing excess bulk material from my blank, starting the shaping process.

Works for wood and foam equally well.

[attachment=5]Ryobi Band Saw.jpg[/attachment]

Draw back, It will remove your fingers! (Be carefull  )

)

Depending on your blade size, it is possible to do some limited scroll work. (Thin Blade)

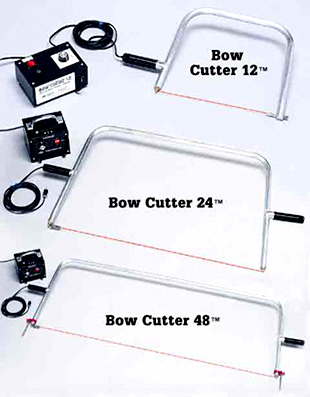

Hand Held Hot Wire Cutters

Hand Held Hot Wire Cutters

When working with foam, carving or cutting, the hot wire cutter is the way to go.

you can make them yourself or buy commercial ones.

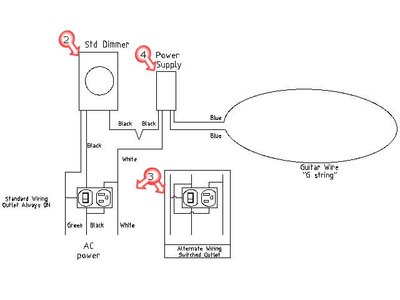

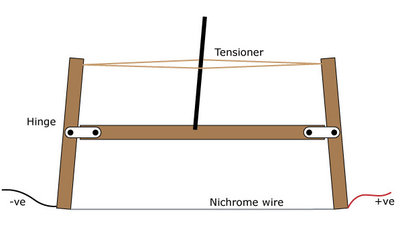

They are not that complicated. Hand held wire cutters are simply a bow to hold the wire and a power source to heat the wire.

[attachment=2]DIY Hot Wire Cutter schematic.jpg[/attachment]

The wire can either be Nichrome (nickel chromium), Piano wire, Gutiar Strings etc.

Power source can be a simple door bell transformer, to a sophisicated regulated power supplies and I will cover those later.

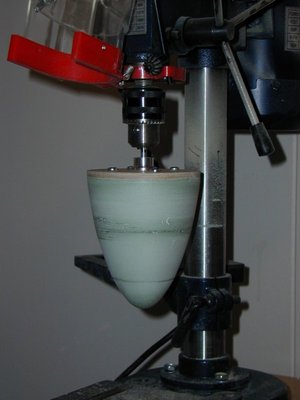

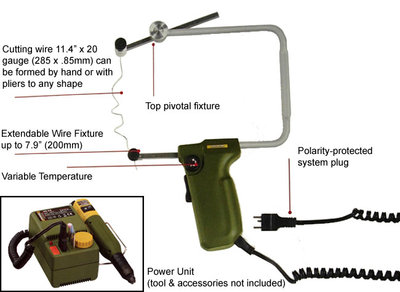

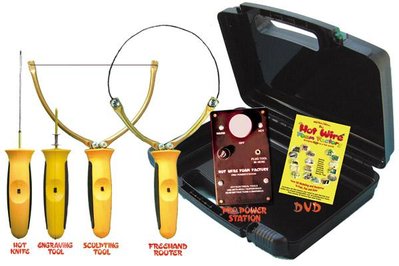

This is a set made by Hot Wire Foam Factory and is available from FRP Games

[attachment=4]4 In 1 Set.jpg[/attachment]

This one is a very simple economy Hot wire cutter made by Woodland Scenics and is available through Micro Mark

[attachment=3]Hand held Wire cutter Woodland.jpg[/attachment]

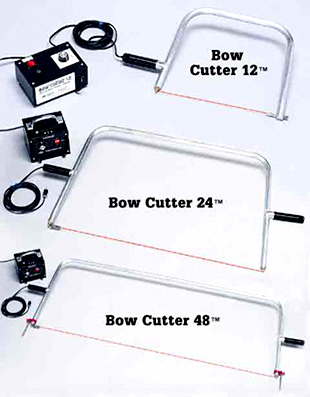

[These are long bows 12" 24" and 48" and are available from Abbeon Cal

[attachment=0]Long Bows.jpg[/attachment]

This one is made by Proxxon and is a premium cutter

You can buy as a set that comes with a rotory tool or you can buy the cutter by it self

I recommend buying the foam cutter separately because there are better rotory tools and I will cover that in a minute.

[attachment=1]Hobby-Hand-Wand.jpg[/attachment]

Check this one out at Proxxon Tools

Next up DIY Hand Held Hot Bows

-

Attachments

-

- Long Bows.jpg (68.56 KiB) Viewed 15045 times

- Long Bows.jpg (68.56 KiB) Viewed 15045 times

-

-

-

- Hand held Wire cutter Woodland.jpg (8.47 KiB) Viewed 15074 times

- Hand held Wire cutter Woodland.jpg (8.47 KiB) Viewed 15074 times

-

-

-

Last edited by

Big Al on Fri Aug 12, 2011 11:58 pm, edited 4 times in total.

By Your Command

-

Big Al

- Command Centurion

- Posts: 1012

- Joined: Tue Jun 07, 2011 3:09 am

- Location: Las Vegas Nevada

Post

by Big Al » Fri Jul 08, 2011 3:04 am

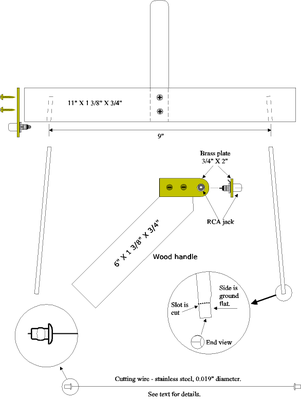

DIY Hand Held Hot Wire Cutters

This section is about Home brew hand cutters and links for plans to build them. Commercially made hand cutters are great! You buy them, plug them in, and start cutting. Home brew cutters work just as good as commercially made ones. The advantage is that you can make your cutters any size you want! You can make them wide or narrow, shallow or deep.

DIY Hand Held Hot Wire Cutters

This section is about Home brew hand cutters and links for plans to build them. Commercially made hand cutters are great! You buy them, plug them in, and start cutting. Home brew cutters work just as good as commercially made ones. The advantage is that you can make your cutters any size you want! You can make them wide or narrow, shallow or deep.

You can make bow handles from a variety of materials such as, Wood, Plywood, Masonite, Partical board, PVC, Peg Board or any type of material that is non conductive. We use these type of bows to cut wing cores with.

Here is a bow made from yard sticks. The Plans are here at Instructables

[attachment=4]Hot-wire-foam-cutter yard stick.jpg[/attachment]

Here is a bow made from PVC. you can buy this one commercialy but is basicly a home brew.

[attachment=3]Hot Wire Cutter PVC.jpg[/attachment]

Here is the link

Moss Foam

This is one I have made and it works great!

[attachment=2]Hot Wire hand_cutter_lg.jpg[/attachment]

Here is the plan

[attachment=1]Hot WIre hand held plans_pic.png[/attachment]

This is a typical bow with an opposing tension spring (Loop of twine twisted with a dowel rod)

[attachment=0]Hot Wire Cutter Bow Drawing.jpg[/attachment]

Here is the link for the plan

Fast Electrics

Bows are basicaly used for free hand cutting and the designs are pretty simple.

You can save money making your own cutters and make as many as you like.

The sizes and widths you can make are endless.

Next Up: Hot Wire Scroll Saws

-

Attachments

-

-

-

- Hot Wire hand_cutter_lg.jpg (14.22 KiB) Viewed 15073 times

- Hot Wire hand_cutter_lg.jpg (14.22 KiB) Viewed 15073 times

-

-

Last edited by

Big Al on Fri Aug 12, 2011 11:59 pm, edited 2 times in total.

By Your Command

-

Big Al

- Command Centurion

- Posts: 1012

- Joined: Tue Jun 07, 2011 3:09 am

- Location: Las Vegas Nevada

Post

by Big Al » Fri Jul 08, 2011 2:10 pm

Hot Wire Scroll Saws

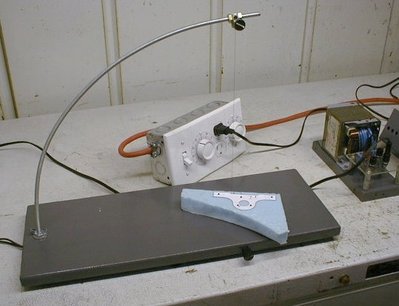

Hot wire scroll saws are a great tool for cutting foam. I will start with commercial cutters and then home brew cutters.

Hot Wire Scroll Saws

Hot wire scroll saws are a great tool for cutting foam. I will start with commercial cutters and then home brew cutters.

A regular scroll saw is a must because it will allow you to make the wood patterns you need for makeing foam parts.

You can cut some foam on a regular scroll but you are limited in thickness and it can tear and shread your edge.

A hot wire scroll is awsome! making clean cuts, allowing you to make intricate cuts on thin and thick blocks.

There are many commercially made hot wire scrolls, but you can make your own.

Again the advantage to making your own is that you can make it as big as you want and home brew machines work just as good as a commercial machine.

Commercial Hot Wire Scroll Saws

Commercial Hot Wire Scroll Saws

This first one is made by Proxxon

This first one is made by Proxxon

and I have used this one many times and it is a great machine.

[attachment=6]Proxxon Hot scroll.jpg[/attachment]

This is a 3D Scroll Table by Hot Wire Foam Factory

This is a 3D Scroll Table by Hot Wire Foam Factory  Very Cool!

Very Cool!

It can be used as a Scroll, Mill, Lathe, very versatile machine!

[attachment=5]Scroll Saw 3D.jpg[/attachment]

This one is also from Hot Wire Foam Factory

This one is also from Hot Wire Foam Factory

and is a simple crafters scroll.

[attachment=4]Crafters scroll.jpg[/attachment]

This scroll is made by Uchida and is available from Amazon

This scroll is made by Uchida and is available from Amazon

[attachment=3]Amazon Scroll.jpg[/attachment]

This one is available from Alibaba.Com

This one is available from Alibaba.Com

and is unique in that it has a raised table with a cavity under the cutter for versitility.

[attachment=2]Hot_Wire_Foam_Cutter 1.1.jpg[/attachment]

This one is availible from Demand Products

This one is availible from Demand Products

and is very expensive

[attachment=1]precisionmodelmaker Scroll.jpg[/attachment]

This next Machine is pretty cool, Very Pricey and is mainly available in europe.

This next Machine is pretty cool, Very Pricey and is mainly available in europe.

[attachment=0]Hot wire Cutter 1.2.jpg[/attachment]

Here is the Link Tech Span Online

There are many more that are available and if you find one you like and you have the means get one.

But you can build anything you want and can save alot of money doing so and a home brew may not be a pretty as a factory made machine, but your home brew will work just as good!.

Next Up: DIY Hot Wire Scroll Saws

-

Attachments

-

-

- precisionmodelmaker Scroll.jpg (6.09 KiB) Viewed 15070 times

- precisionmodelmaker Scroll.jpg (6.09 KiB) Viewed 15070 times

-

-

- Amazon Scroll.jpg (7.08 KiB) Viewed 15070 times

- Amazon Scroll.jpg (7.08 KiB) Viewed 15070 times

-

-

-

- Proxxon Hot scroll.jpg (10.46 KiB) Viewed 15070 times

- Proxxon Hot scroll.jpg (10.46 KiB) Viewed 15070 times

Last edited by

Big Al on Fri Aug 12, 2011 11:59 pm, edited 3 times in total.

By Your Command

-

GoldCylon

- Founder

- Posts: 6948

- Joined: Fri Dec 02, 2005 3:02 pm

- Location: Sacramento

-

Contact:

-

Post

by GoldCylon » Fri Jul 08, 2011 8:10 pm

I have a battery operated 12" bow cutter, and was low cost. Somewhere around $10.00 about 20 years ago.

-

Big Al

- Command Centurion

- Posts: 1012

- Joined: Tue Jun 07, 2011 3:09 am

- Location: Las Vegas Nevada

Post

by Big Al » Sat Jul 09, 2011 3:25 am

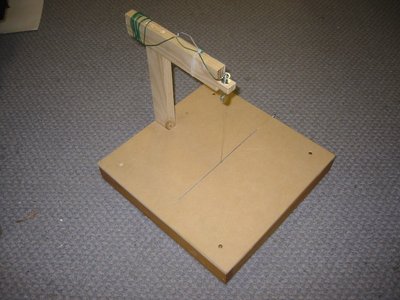

DIY Hot Wire Scroll Saws

There are alot of DIY blogs, articles, Discussion boards etc. on this subject

DIY Hot Wire Scroll Saws

There are alot of DIY blogs, articles, Discussion boards etc. on this subject

I found there are alot of designs for home brew units, from really basic slap together types to designs that were well thought out and designed like commercial units.

I have gathered some examples, some with links and plans and some I could only find pics of but if someone wated to duplicate them it wouldn't be hard.

I love making my own machines. I don't think you should have to spend hundreds to thousands of dollars for a machine that you need. Especialy Vacuum form machines or hot wire tools. besides it gives you a certain amount of satisfaction when you can create a part with a machine that you built! It's kinda primal to me like the tribesman who cuts the tree, makes the bow and arrows, hunts and kills the deer with his bow an arrow, then cooks and eats the deer. That meat will taste much better than if you just go to the store and buy it!

Maybe that's a little extreme, but that's just me.

Ok Enough blathering!

This machine was made by Andrew Tomasch

and is a good example of MacGyver-Ing

[attachment=6]Andrew Tomasch Hot Wire.jpg[/attachment]

This machine was made from parts bought from Home depot and the power supply is an old model train transformer

This next one is very popular with modelers and is made by joeboy@hhh. org

[attachment=5]hotwire_foam_cutter_joeboy@hhh.org.jpg[/attachment]

Here is another machine built by W. E. Johns at Gizmology

[attachment=4]hotwirefront gizmology.jpg[/attachment]

This one was built by Daniel B. Hartman and the name of his site is Dan's Workshop

[attachment=3]foam_cutting_table Dan's Workshop.jpg[/attachment]

Here is another Hot Wire machine Dan built and I thought is was so cool that it just went on my list!

[attachment=2]00-The_foam_cutting_lathe Dans Workshop.jpg[/attachment]

This one I found on The RPF site and was made by Rick Hanson

[attachment=1]table1rpf.jpg[/attachment]

Here is one I found at Model Airplane Pages.Com

Designer and builder Unknown

[attachment=0]vert_cutter_lg.jpg[/attachment]

More to come

-

Attachments

-

- vert_cutter_lg.jpg (9.2 KiB) Viewed 15062 times

- vert_cutter_lg.jpg (9.2 KiB) Viewed 15062 times

-

-

-

-

- hotwirefront gizmology.jpg (10.54 KiB) Viewed 15062 times

- hotwirefront gizmology.jpg (10.54 KiB) Viewed 15062 times

-

-

Last edited by

Big Al on Sat Aug 13, 2011 12:01 am, edited 2 times in total.

By Your Command

-

Big Al

- Command Centurion

- Posts: 1012

- Joined: Tue Jun 07, 2011 3:09 am

- Location: Las Vegas Nevada

-

Big Al

- Command Centurion

- Posts: 1012

- Joined: Tue Jun 07, 2011 3:09 am

- Location: Las Vegas Nevada

Who is online

Users browsing this forum: No registered users and 1 guest